The science behind the sword

by Ailsa Harvey · 04/02/2020

Discover the ancient art of forging a deadly weapon

Swords were the first tools designed solely to kill. There were other weapons before swords, such as spears, axes and knives, but they were all originally intended for other purposes before being adopted as instruments of war. The spear was originally made for hunting, the axe for chopping wood, while knives have many functions. But the sword exists only to kill people.

Initially, swords were as much status items as weapons. These first swords, appearing from around 3000 BCE, were forged from bronze, an alloy of copper and tin. As the technology required to forge bronze was still new, and bronze itself quite rare, these early swords were very uncommon, highly prized and a sign that the person carrying them was extraordinarily wealthy and powerful. One such example is the bronze sword, shaped like a sickle, that was buried with Tutankhamun circa 1327 BCE. Called a khopesh, the sword of the pharaoh was sharpened on its outside edge, with the tip used both as a hook and a club.

The technology to make bronze spread around the Mediterranean basin, and trade evolved to bring tin from mines in the Iberian Peninsula and Cornwall to the forges of the eastern Mediterranean. As a result, swords became more and more widespread, until whole armies carried them. The Minoan, Sumerian and Assyrian empires were all carved out by armies carrying bronze swords. But iron changed everything. The metal itself is common, strong and durable, and will produce a weapon that is both flexible and tough. The Hittites were early adopters of this technology, using iron weapons to form their empire from 1600 BCE onwards. With the Hittites showing the way, iron became the new material from which to forge swords.

The problem with iron swords, though, is that iron bends. To make a sharp, hard, cutting edge, you need steel – an alloy of iron and carbon. In the first millennium BCE, the Etruscans began to create alloys of steel and iron, making swords that had edges hard enough to cut through armour, yet which were also sufficiently flexible to withstand the shock of battle.

The Romans developed Etruscan technology, creating the blade that characterised the Roman military machine: the gladius. This short, stabbing sword was the weapon of the legionary and, armed with it, the Romans created their empire. But it was the longer sword employed by their cavalry, the spatha, that outlived Roman rule. As the Western Empire declined, many of the barbarian groups who were employed to defend it used the spatha. The weapon became the prototype from which the swords of the Anglo-Saxons and Vikings, the high points of western sword making, developed.

Perhaps the finest example of these swords is the one found at Bamburgh in Northumberland. Excavated in 1960 and rediscovered in 2001 (just in time, as it was about to be thrown into a skip), the Bamburgh Sword was forged in the 7th century. About 76 centimetres long when first made, the sword was passed down through the centuries until, some 300 years after it was forged, it broke. As an heirloom of kings and earls, the sword was not thrown away, but buried, until archaeologists excavated it, although at first they did not realise what they had found.

The Bamburgh Sword was made from six strands of iron, pattern-welded together. No other sword has been found with more than four. In pattern welding, the iron strands are heated, twisted and hammered together, over and over again. When finished, pattern-welded swords have striking swirling designs on them.

It was this tell-tale pattern that led, in part, to the end of pattern-welded swords. Every warrior wanted a weapon like this and, by the later Viking Age, armies had grown to a thousand or more men. In response, crafty swordsmiths began producing fake versions of these blades, which had an ordinary iron core and a thin pattern-welded layer on top.

With the arrival of massed armies, swordsmiths started to forge simpler, easier-to- make blades. The design of the swords

continued to change through the following centuries, to suit the fighting styles of the men carrying them. Blade styles also changed as armour improved, making it harder to cut through with a sword’s edge. As a result, the point of the sword became more important, being sharpened and hardened so that it could punch a hole through an enemy’s armour. Despite bullets largely replacing blades on battlefields, swords continued to be employed by soldiers into the 20th century, being used widely during the Russian Civil War (1918-1920) and the Sino-Japanese War (1937-1945).

Forging the blade

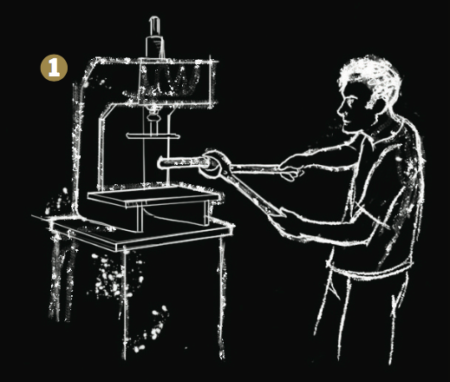

1. Choosing

The iron made the sword. Choosing the best metal was the most important part of making a good blade. However, apart from the occasional meteorite, there is very little pure iron on Earth. For sword making, iron was often obtained from bogs or mined; bog iron is carried in liquid form into the bog, then concentrated by anaerobic bacteria, producing small lumps of iron. This source of iron is renewable, as new lumps appear in 15 to 20 years.

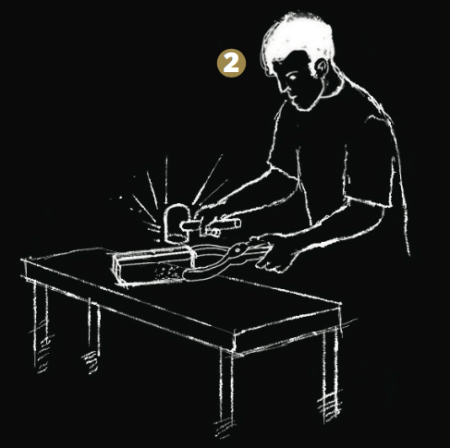

2. Forging

Forging is when the smith hits the hot metal with a hammer over and over again, working it into shape. The best swords fuse iron and steel, and heating the metals makes thousands of tiny welds, joining the two materials together. Forging also spreads any impurities evenly through the sword, reducing the chance of the weapon breaking.

In the best swords, bars of good iron are twisted together, further spreading out any impurities. The bars are welded into a solid core, and the steel edge welded on to the core.

3. Annealing

As the swordsmith is forging the blade, they will usually return it to the heat several times, and let it cool again without working on it. This helps to reduce irregularities in the blade. Once it has been shaped, the sword is annealed by heating it to a precise temperature and allowing it to cool very slowly. This is done either by allowing the forge fire to cool, or by burying the sword in hot sand.

4. Grinding

Swordsmiths through the centuries have used different methods to grind the blade, from water-powered wheels to sand on leather, but hand files were the most common tools employed. The aim of grinding is to remove the material that cannot easily be removed by the forging process. The fuller – the groove down the middle of the sword – and any engraved designs are also added at this stage.

5. Hardening

The shaped sword is reheated until it glows a dull orange colour. At this heat, the metal becomes non-magnetic. The sword is then quenched in water. This helps to line up the crystalline structure of the iron and steel in the sword and makes it harder. But quenching can also make the sword brittle. To overcome this, smiths must heat the blade again, for the next stage in making the sword.

6. Tempering

To overcome the brittleness produced in the hardening, the sword has to be reheated to a lower temperature than before. In the days before temperature gauges, this was done by colour; the smith heats the sword until the edge is a straw colour, and the centre – with its thicker metal – a deep purple. The blade is then slowly cooled. This slow cooling reintroduces some flexibility into the sword, making sure it does not break in battle

7. Completion

Although the sword is now forged, it looks dirty and crusted, so it has to be cleaned. Abrasives, such as sand on leather, are used to file and clean the sword, until it is ready for sharpening on a whetstone. After a final sharpen, pattern-welded swords are etched to highlight the pattern on the blade. The most impressive swords have hilts made of precious metals, with jewels inset, while the pommel and guard are adjusted to keep the weapon balanced. The sword is now ready for use.

This article was originally published in How It Works issue 90

For more science and technology articles, pick up the latest copy of How It Works from all good retailers or from our website now. If you have a tablet or smartphone, you can also download the digital version onto your iOS or Android device. To make sure you never miss an issue of How It Works magazine, subscribe today!