How is olive oil made?

by Ailsa Harvey · 09/10/2019

From brach to bottle, discover the fascinating process of extracting this delicious and nutritious liquid gold

Whether added to the pan before cooking, or enjoyed straight out of the bottle with some fresh bread, olive oil is a tasty and versatile staple in kitchens all over the world. The majority is produced in the Mediterranean, the olive tree’s native home, and the process begins with picking the fruit.

At least 4.5 kilograms of olives are needed to produce one litre of oil, and they are at their prime for only a few weeks a year, so picking needs to be done quickly. However, as olives are a soft fruit, they must also be treated with care, as any bruising can cause the oils to degrade. Large-scale farms use tree-shaking devices to encourage the ripe olives to drop, and then catch them in nets before they hit the ground.

Once they are at the processing plant, the olives pass through several different machines

to extract the oil. Here, speed is also of the essence, as once the olives have been crushed,

exposure to air reduces the oil’s quality. Some plants can process three tons of olives in just one hour. However, during the malaxing (mixing) stage, a longer mix extracts more oil with a more developed flavour, so many modern systems use closed mixing chambers full of a harmless gas, such as nitrogen, to prevent oxidation during a longer mix. The amount of oil produced can also be increased by adding heat or more water during mixing, but this also reduces the product’s quality.

To be classed as virgin or extra virgin, the oil must be kept below 27 degrees Celsius during

processing to ensure that it is ‘cold pressed’. Once bottled, it should be stored (for no longer than two years) in a cool, dark cupboard to preserve its flavour and healthy properties

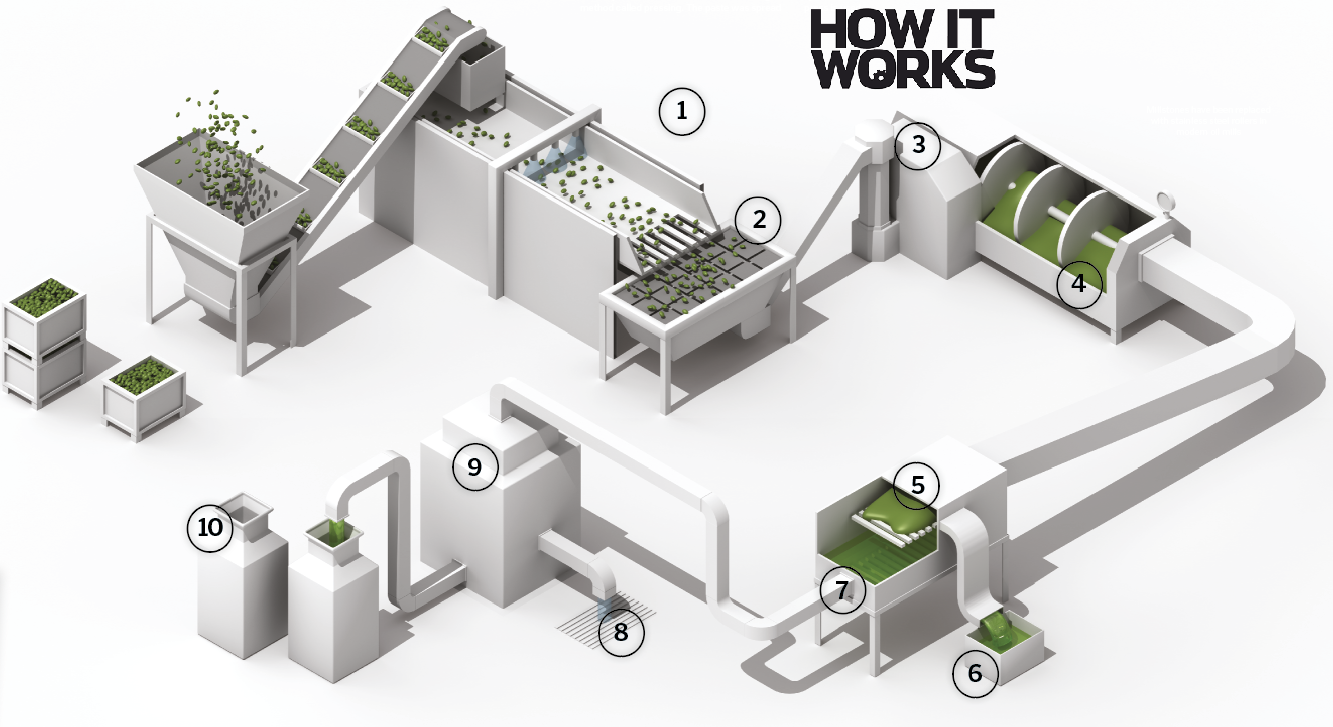

The olives are washed with water to remove any soil or pesticides that may contaminate the oil.

Any leaves, twigs and other types of debris are filtered out through grids prior to crushing.

The olives are crushed and ground into a pulp using stainless steel rollers, releasing the oil from the olive cells.

Water is mixed with the paste for 20-45 minutes to allow small oil droplets to combine into bigger ones.

As water and oil do not mix they can be easily separated from each other and the solid material, although this may also be done using a centrifuge.

The solid material extracted is called pomace and contains a low-quality residual oil that can be extracted later.

Instead of decanting, most modern facilities use a centrifuge that spins at high speeds to separate the oil from the pulp.

The extracted water contains chemical compounds that can be extracted for pharmaceutical, nutritional and cosmetic applications.

The oil may then be refined to reduce acidity and bitterness, bleached to remove colour and pesticides, or deodorised.

The oil is stored in nitrogen-filled stainless steel containers to prevent oxygen from breaking it down.

For more science and technology articles, pick up the latest copy of How It Works from all good retailers or from our website now. If you have a tablet or smartphone, you can also download the digital version onto your iOS or Android device. To make sure you never miss an issue of How It Works magazine, subscribe today!