How is money made?

by Ailsa Harvey · 16/05/2020

From workshop to wallet, how does the world's money reach our back pockets

(Image source: Pixabay)

As online banking and contactless cards continue to grow as our preferred method of payment, physical money may one day be a thing of the past. However, with more than 3.6 billion Bank of England notes in circulation, making money is still a thriving business, one that’s been around for thousands of years. Civilisation began this economic journey through bartering (the trading of items deemed of equal value) around 9000 BCE. It wasn’t until around 600 BCE that Lydia, an ancient civilisation now part of Turkey, introduced the world’s first coins as currency, made from a naturally occurring mixture of gold and silver called electrum.

As the concept of currency spread across the globe coins gave way to paper notes. Though sometimes referred to as ‘paper’ currency, traditional banknotes are not made from pulped wood but in fact cotton, or in the case of the US dollar, a blend of cotton and linen. Cotton bales are ‘plucked’ by heavy machinery before being filtered for imperfections and bleached. Fibres are then pressed to remove water and feed through rollers to form sheets. Watermarks and security features are placed on the sheets before final designs are printed and the notes are cut.

These polymer notes are more resistant to dirt and moisture and have a stronger composition than their paper counterparts. Made from durable plastic compounds such as polyethylene terephthalate (PET) or biaxially oriented polypropylene (BOPP), the plastic notes start out as small pellets. These pellets are melted, and then stretched into an enormous bubble to cool that can stretch up to five storeys tall. Once the base of the bubble has cooled sufficiently it is rolled out into a sheet. This then passes through an infrared gauge to check the thickness. Once they have been quality checked the sheets of plastic are rolled up, packaged and sent out for the final banknote designs to be added.

In the first half of 2018, about 223,000 counterfeit banknotes were discovered, so money makers have had to develop different ways to ensure the safety of their notes. Each note, depending on the country of origin, contains several security features that distinguish the real notes from the fakes. Polymer notes are much tougher to make forgeries of, and the addition of transparent windows, foils, holograms and ultraviolet treatments are used to verify their authenticity. Security measures are even applied to the artwork, with hidden designs, textures and raised print known as intaglio printing often used to foil would-be forgers.

Putting a price on plastic

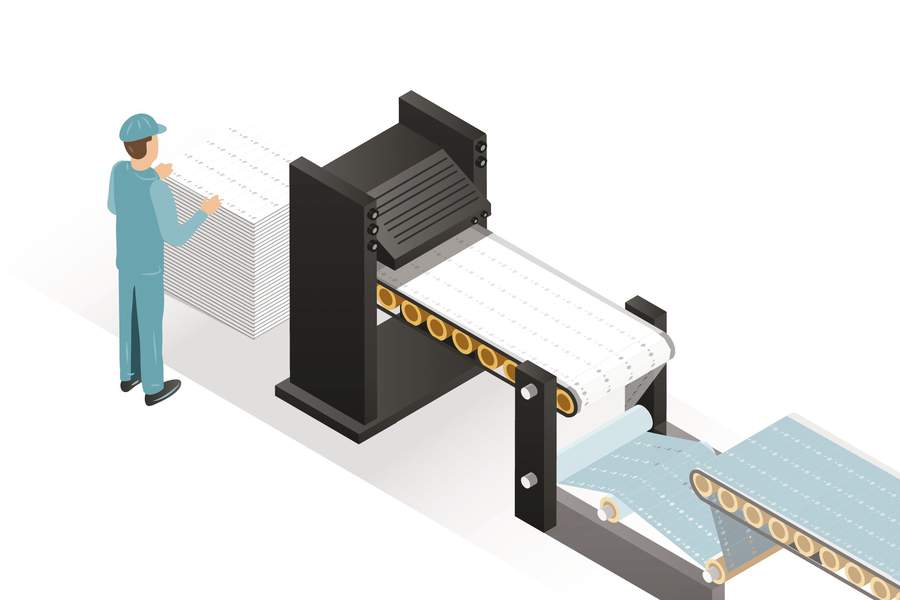

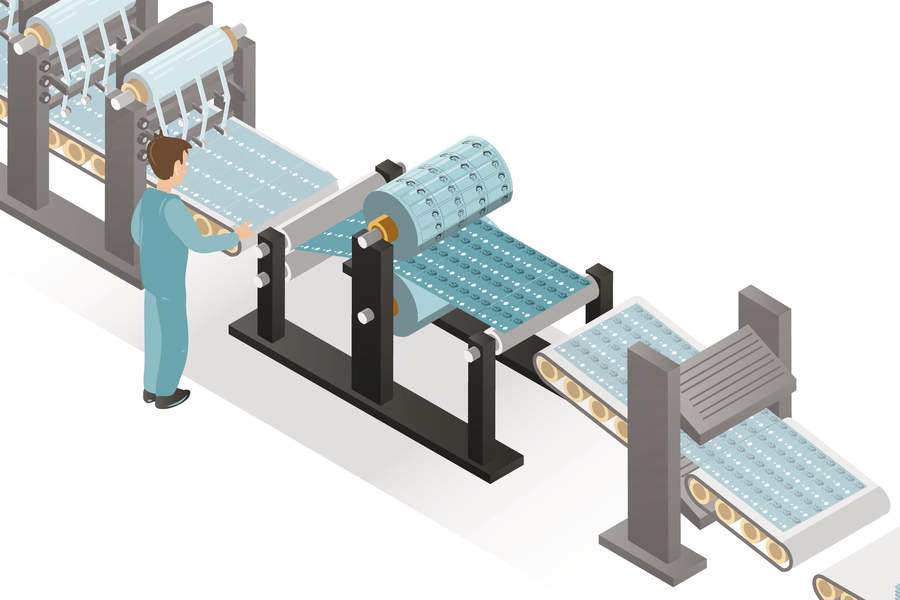

1. Blank sheets

Imported sheets of polymer substrate, housing the transparent window, are loaded into the printing process.

2. Base print

Computer-generated background designs are then printed onto both sides of the polymer sheets.

3. One at a time

Printed sheets are then fed individually into a foiling machine.

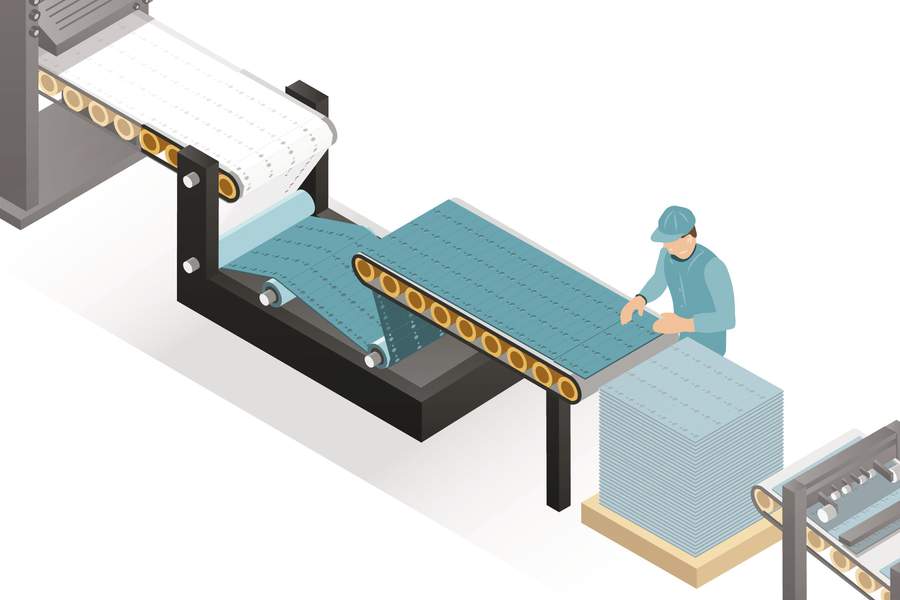

4. Applying foil

From a tape, strips of foil are applied to the uncut polymer sheets.

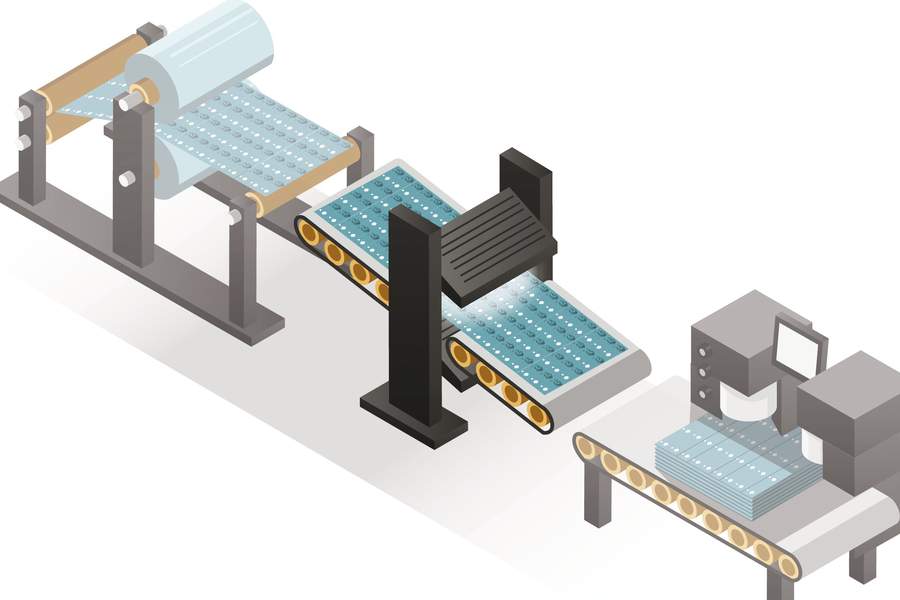

5. Security features

Portraits of county’s iconic fi gureheads are then added to either side, such as Queen Elizabeth II. The printing for these portraits is typically intaglio or textured for security purposes, making them much harder to copy.

6. UV treatment

Sheets are then treated with ultraviolet light as a security measure.

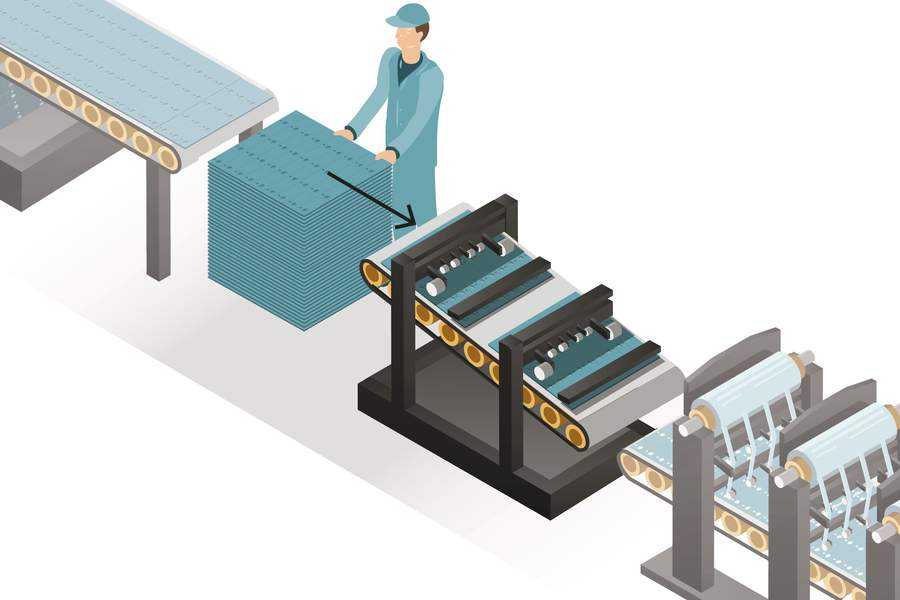

7. Making the grade

Quality control checks are carried out and the polymer sheets are counted.

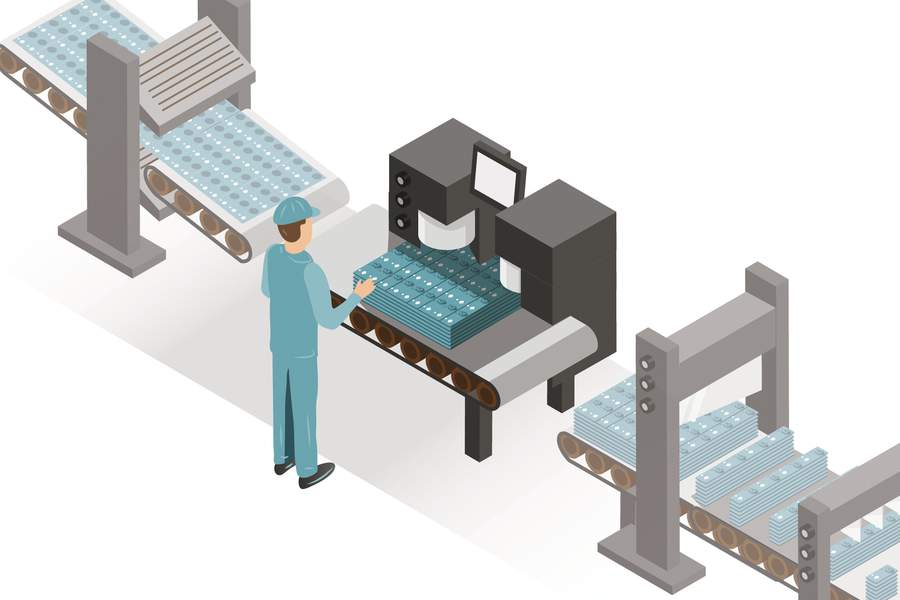

8. Cutting to size

In order to separate the individual notes, stacks of sheets are put through a guillotine.

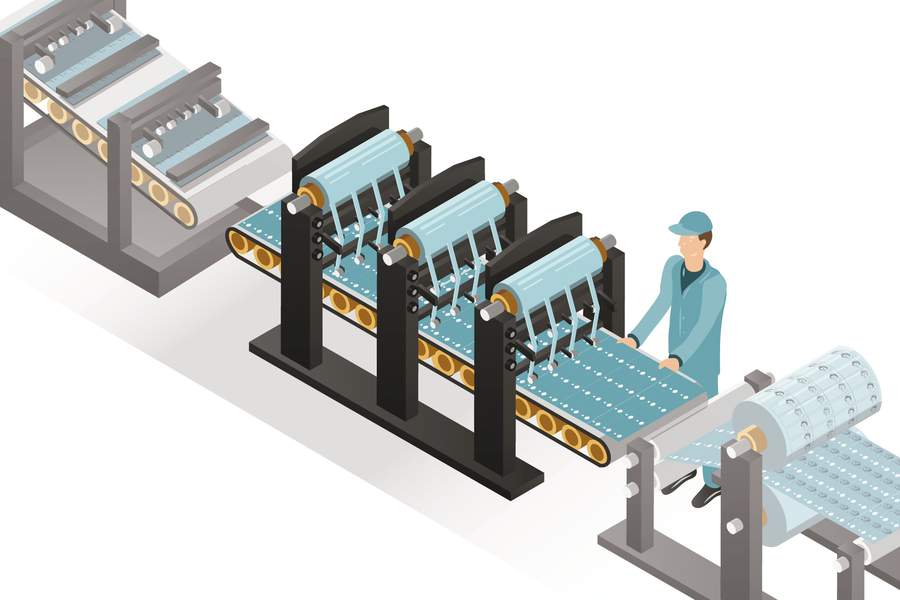

9. Final checks

Notes are then stacked, checked, tested and counted again.

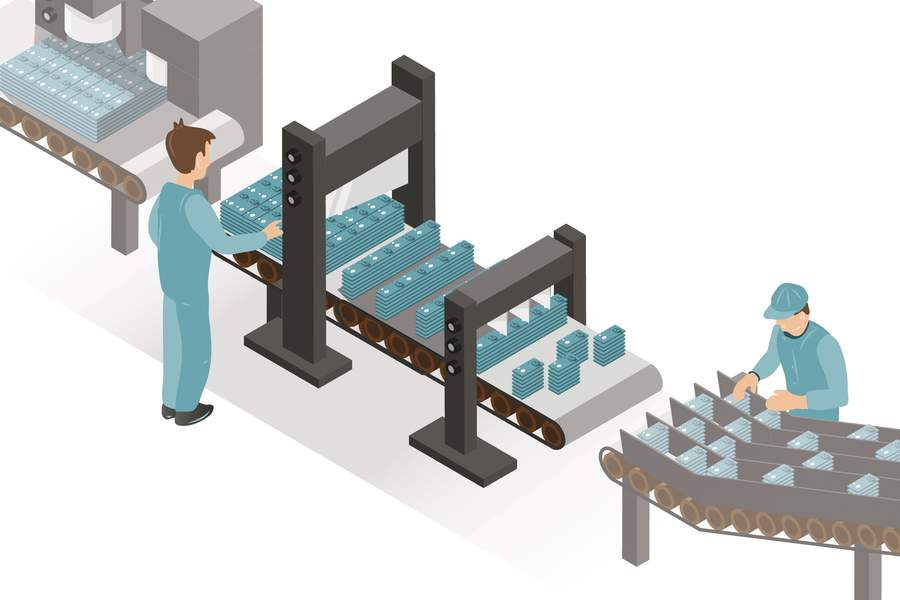

10. Off to the banks

Finally, notes are packaged in bundles and stored in secure cages ready for transport.

(Illustrations by Ed Crooks – Future PLC)

This article was originally published in How It Works issue 122, written by Scott Dutfield

For more science and technology articles, pick up the latest copy of How It Works from all good retailers or from our website now. If you have a tablet or smartphone, you can also download the digital version onto your iOS or Android device. To make sure you never miss an issue of How It Works magazine, subscribe today!