Inside the world’s largest engine

by Ailsa Harvey · 09/02/2021

How this huge diesel engine is winning the race at sea

Inside the engine of a car, a line of cylinders works to ignite fuel and provide these vehicles with power. Most cars will have four, six or eight cylinders– some supercars even have 12! Usually the more there are in an engine, the more impressive the power output will be. But no matter how satisfied you are with the power you display as you cruise around the neighbourhood, there is one engine with the ability to make all others feel inferior.

Meet the 14RT-flex96C, a 14-cylinder beast designed to propel the biggest most unwieldy machines in the world. This engine is suitable for no car, as it stands taller than a four-storey building. It was created by Finnish manufacturer Wärtsilä and first put to use in 2006. It is easy to be taken aback by the sheer size of this engineering feat and to overlook its equally smart design. Faced with the demand for greater power in marine engines, the engineers working on the RT-flex went above and beyond what was originally deemed practical. Previously only 12 cylinders were used on ships. However, this machine takes on two more cylinders while adding extra control, efficiency and longevity to the engine

Producing power: How does this series of cylinders generate energy?

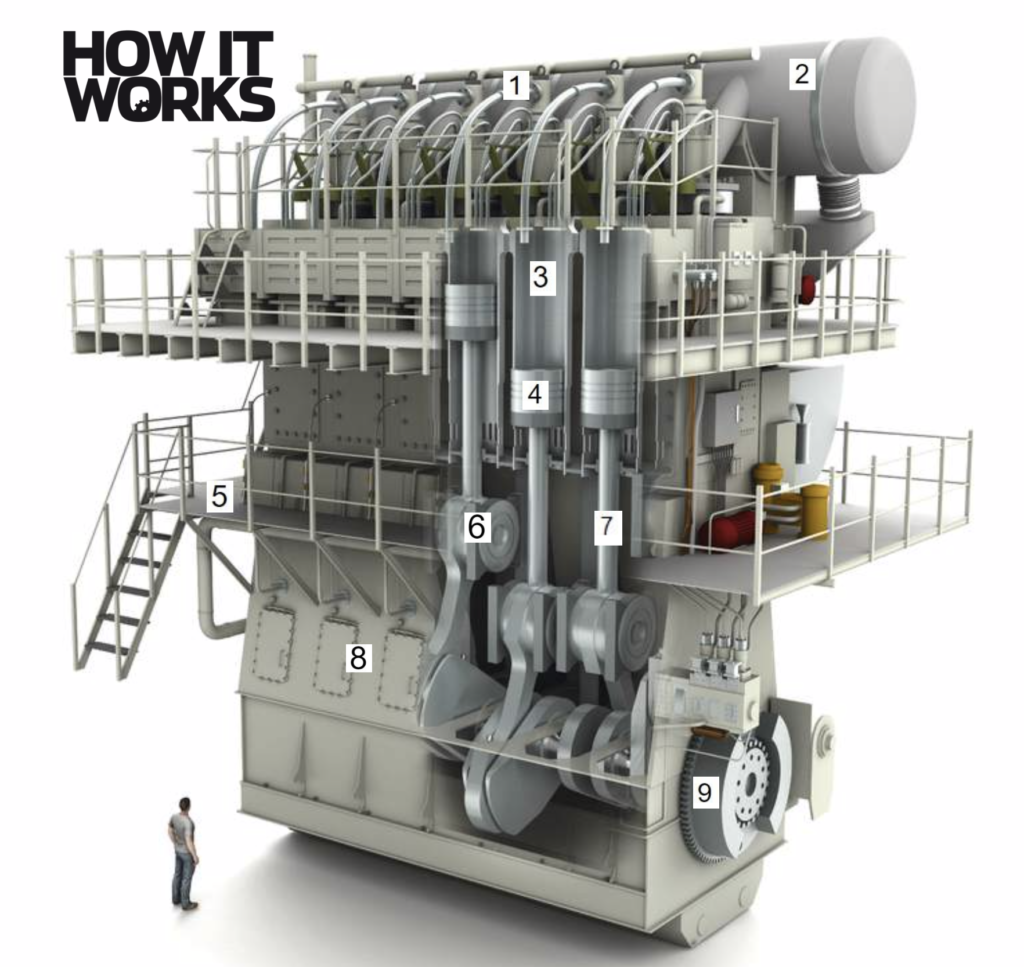

1. Fuel injection

Being electronically controlled, the fuel injection valves can be manipulated individually, rather than together. When injected into the cylinder and combined with air, fuel is ready for a combined explosion.

2. Exhaust

Exhaust fumes are kept in this chamber to be released or reused. The engine recycles its exhaust for optimum efficiency. Mixing with fresh air, it is reverted back into the engine to be used again. This increases fuel efficiency by 12 per cent.

3. Cylinder

The engine’s cylinders are where the internal combustion takes place. The largest engine has 14 of these, with each producing a power of 5,720 kW.

4. Piston

This gas-tight component moves according to the volume and pressure inside the cylinder. Being connected to the rod, its movement initiates the entire rotor system.

5. Platforms for people

The huge scale of this engine means platforms and stairs are needed with different levels for service crew to reach required parts.

6. Crosshead

RT-flex is a crosshead diesel engine. This means it has a block between the rotational and longitudinal mechanisms. Without this the sideways movement, the rotor would push the piston rod against the side of the cylinder, wearing out the engine.

7. Connection rod

This lever transfers the kinetic energy from the piston to the crankshaft. It does this by complementing the actions of both systems as it connects them.

8. Bedplate

This is the foundation of the engine. Being so large, the RT-flex bedplate consists of multiple parts welded together. Its strength is needed to support the weight of the entire moving structure and keep all its components aligned.

9. Flywheel and crankshaft

The engine’s crankshaft converts the vertical movement of the rods into rotational energy, causing the flywheel to turn. The flywheel stores the rotational energy . When installed into the ship the engine connects to the propellers here to push the vessel through the water. This rotational energy can turn propellers 102 times a minute.

What is the engine used for?

Where can such a colossal engine be found? At present these enormous engines are powering some of the world’s largest ships across the ocean at much greater speeds than their rivals. The first ship to be installed with this engine is still in use. Carrying cargo from China to the US, the Emma Mærsk can reach its destination four days earlier than others with smaller and less powerful engines.

Emma Mærsk stretches nearly 400 metres in length, making it one-and a-half times the length of the Titanic and twice its width. As it carries up to 11,000 shipping containers, each six metres long, it is worthy of housing the largest engine ever made. Travelling at over 25.5 knots may not seem outrageously fast, but without this engine at the core its competitors only manage around 20 knots. Over long voyages across the sea, that’s a lot of time saved.

Some of the huge numbers surrounding this engine might fill you with concern for the environment, but the engine is in fact extremely efficient for its size, making it one of the least polluting compared to other ship engines. Equipped with combustion control, heat from the engine that would usually enter the atmosphere as a waste product can be used for other processes on the ship. Additionally, any exhaust gases that are not reused for combustion can be passed through a steam generator. The steam extracted is then used to power electrical generators as it spins turbines. These processes help to reduce the emissions produced by the engine and provide further power beyond propelling the ship.

For more science and technology articles, pick up the latest copy of How It Works from all good retailers or from our website now. If you have a tablet or smartphone, you can also download the digital version onto your iOS or Android device. To make sure you never miss an issue of How It Works magazine, subscribe today!