Modern paper mill: How is paper made?

by Scott Dutfield · 01/05/2019

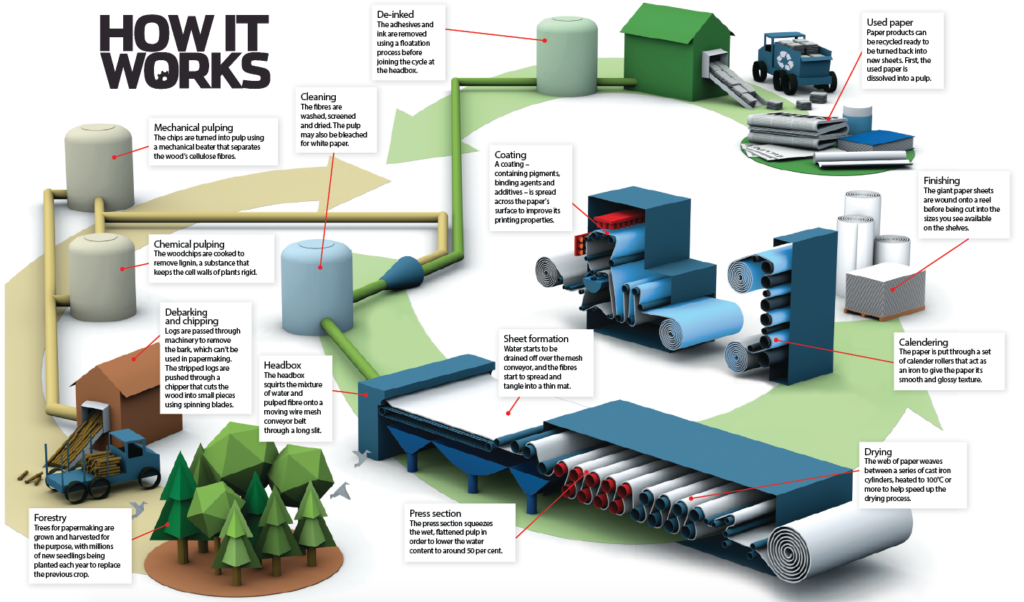

The chemistry and engineering involved in transforming pines into pages

From our favourite books or magazines to the pages of our notepads or sketchbooks, we have used paper to help share ideas and information since the process was invented in China in the second century CE. Papermaking is a craft that has remained fundamentally unchanged throughout the years, but modern technology has dramatically increased the quality and efficiency.

All paper products, like the pages of this magazine, for example, start out life as a tree. Its bark is removed and the remaining wood is chipped, mashed into a pulp and processed by machines to make it smooth and durable.

Before the papermaking process was industrialised our ancestors would have used bone, bamboo or papyrus to jot down their ideas or keep records. The first handmade paper from wood was creating by diluting the pulp into a soup of cellulose fibres and then sieving the material over a mesh-like screen, which encouraged the fibres to interweave. The resulting mush was then pressed to remove water, leaving a matted sheet.

It wasn’t until the 19th century – when the steam-driven papermaking machine was invented – that people were able to produce paper on a large scale. With the fountain pen and the pencil invented around a similar period, wood paper became commonplace, revolutionising economies and societies around the world. Printed academic texts, newspapers and books all became available before the closing of the century.

The industry is now dominated by North America, Europe and east Asia, with mills around the world producing some 400 million tons of paper every year. The machines involved in the process perform largely the same steps as traditional papermaking but have made the process faster, consistent and more efficient. They have four distinct sections for forming, pressing, drying and calendering.

The most common devices used today are Fourdrinier machines, which produce paper at an incredible rate of over 60 kilometres of sheets per hour. With these hi-tech methods we produce more than enough paper to stock our stationary cupboards, offices and schools.

The journey from the forest floor to A4

This article was originally published in How It Works issue 110, written by Charlie Evans

For more science and technology articles, pick up the latest copy of How It Works from all good retailers or from our website now. If you have a tablet or smartphone, you can also download the digital version onto your iOS or Android device. To make sure you never miss an issue of How It Works magazine, subscribe today!