Drilling for oil offshore

The world produces over 82 million barrels of oil every day, much of it in harsh conditions, miles from shore and safety if an emergency happens. So how is it done?

Oil has been around for millions of years, located deep below the land or sea where it became trapped under layers of permeable rocks or slowly seeping to the surface. Although examples of oil drillingwas documented in 4th Century China, the first modern oil gathering structure was built in 1897 and by 1928 mobile rigs consisting of a simple barge with a drill mounted on top had set the scene for a revolution that fuelled Western industrial dominance for the next century. Over 82 million barrels of oil are produced every single day, a process that usually starts with a range of surveys; from geographical and geomagnetic surveys to the deep echo sounding or seismic reflection surveys that pinpoint the likely location of a substantial deposit. Only then, and after the necessary permits have all been obtained of course, can the rigs move in – multi-million-pound structures and teams of professionals that locate, make the well safe and finally drill down to its precious commodity. Today, there are over 40,000 oil fi elds around the world, with most offshore drilling undertaken in the Conti nental shelf – the sunken perimeter of a continent’s original glacial shape. From the $100 million monsters that plumb the deepest waters in the Gulf of Mexico to the smaller North Sea structures that nevertheless have to withstand 90-knot winds and 60-foot waves. Mobile rigs are usually reserved for exploratory work, owned by private contractors and leased to the oil companies who then have limited time to find, tap and process their precious bounty. Larger manned platforms and spars can service up to 30 wellheads, tapping into multiple wells up to five miles from the platform itself.

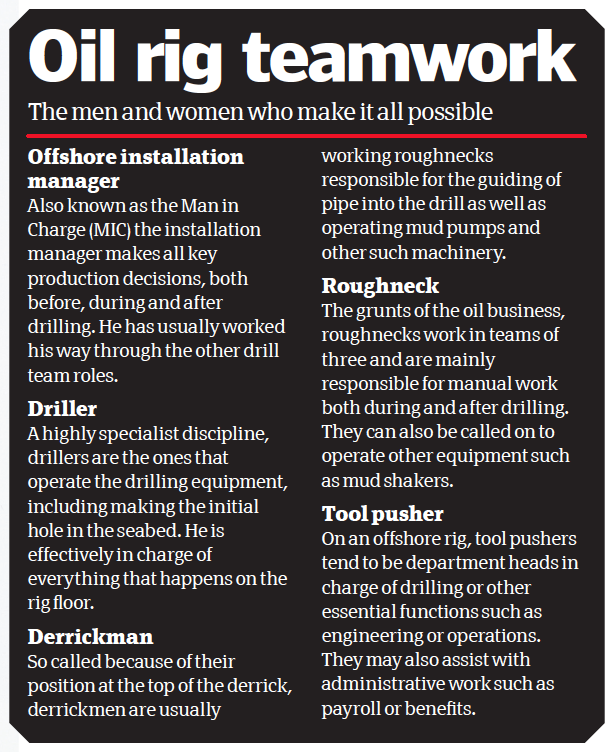

nental shelf – the sunken perimeter of a continent’s original glacial shape. From the $100 million monsters that plumb the deepest waters in the Gulf of Mexico to the smaller North Sea structures that nevertheless have to withstand 90-knot winds and 60-foot waves. Mobile rigs are usually reserved for exploratory work, owned by private contractors and leased to the oil companies who then have limited time to find, tap and process their precious bounty. Larger manned platforms and spars can service up to 30 wellheads, tapping into multiple wells up to five miles from the platform itself.

Life on an oil rig

Required to work for up to six months a year, oil workers are well compensated for the undeniably hazardous conditions they work in. Wages are typically higher than in similar engineering disciplines and the larger platforms and spars come complete with facilities more appropriate to a cruise ship than a floating factory. These can include private rooms for the 100+ crew, cinemas, 24-hour restaurants and even gyms. Supplies are usually brought in by helicopter or ship, making oil platforms better stocked than most workplaces and significantly more important to the local economies they reside in. It is estimated that every offshore worker supports up to ten more in local industries such as food, transport or maintenance. However, the dangers are constant and largely unpredictable. Offshore drilling involves not just dealing with highly flammable oil and gas, with the added danger of this being pumped out at exceptionally high pressures, but also extreme wind and sea conditions. When danger strikes, support is often miles away by helicopter or ship and despite the high levels of training and increasingly safe equipment, offshore fatality rates have been on the rise in recent years. In addition to this, workers are often prone to alcoholism or drug abuse to overcome the isolation and gruelling 12-hour shifts.

For more tech news, pick up your copy of Issue 102 from all good retailers or from our website now. If you have a tablet or smartphone, you can also download the digital version onto your iOS or Android device. To make sure you never miss an issue of How It Works magazine, subscribe today!